R&D and Manufacturing

Our products are developed in-house at the Advanced Technology Development Center, and our three plants in Japan supply high quality and stable products. Read about our R&D and manufacturing bases and manufacturing policy.

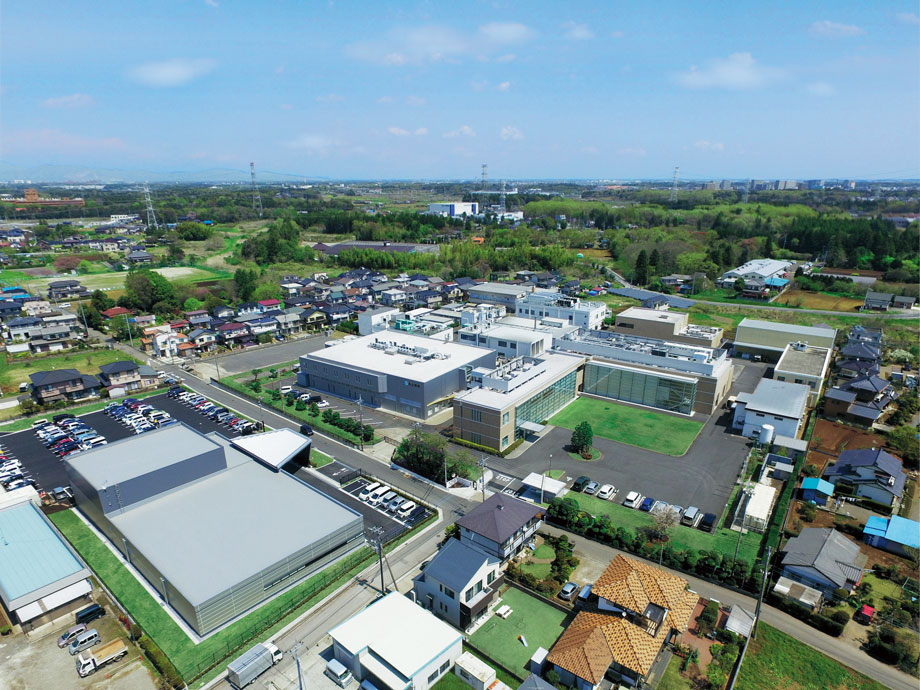

Advanced Technology Development Center / Tsukuba Plants

| Location | 2-9-22 Takamihara, Tsukuba-shi 300-1252 [Google Map] |

|---|---|

| Main Role |

|

| Representative products |

In-house production:

Vaccines for cattle, swine, poultry, cultured fish, dogs, and cats, diagnostic kits for cattle, and therapeutic drugs for cattle

Imports:

Vaccines for cows and chicken, Diagnostic kits for dogs and cats, and for swine

|

Saitama Plants

| Location | 9-10 Kabutoyama, Kumagaya, Saitama 369-0104 [Google Map] |

|---|---|

| Main Role |

|

| Representative products | Antibiotic injections, vitamin injections, anti-inflammatory analgesics, infusion, anthelminthics for animals, mixed feed, and feed additives |

Hiroshima Plants

| Location | 36 Shinfukushiro, Tojo-cho, Shobara, Hiroshima 729-5112 [Google Map] |

|---|---|

| Main Role |

|

| Representative products | Feed additive drugs, oral powder drugs, water additive drugs, racehorse drugs, aquaculture drugs, feed additives, and mixed feed |